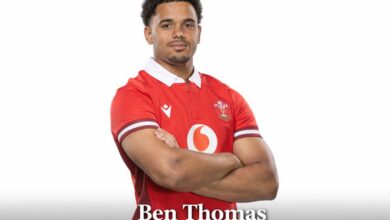

Shaun Williamson – The Versatile English Actor Who Turned Fame, Failure, and Reinvention into a Legacy

From EastEnders to Barrioke: The inspiring journey of a man who refused to fade away from the spotlight.

Table of Contents

ToggleIntroduction

Shaun Williamson is a celebrated English actor, entertainer, and television personality best known for his unforgettable portrayal of Barry Evans in the BBC soap EastEnders. Over the years, Shaun’s career has gone far beyond his iconic soap role, transforming him into a respected stage performer, writer, quiz expert, and live entertainer. His story reflects persistence, reinvention, and the courage to embrace both triumph and struggle.

Born in Maidstone, Kent, Shaun’s journey from a working-class background to national fame is a story of determination and creative evolution. Whether performing on screen, singing before thousands in his “Barrioke” shows, or appearing in British quiz competitions, Shaun Williamson continues to charm audiences with his humor, humility, and authenticity.

Quick Bio

| Full Name | Shaun Williamson |

|---|---|

| Date of Birth | 29 November 1965 |

| Birthplace | Maidstone, Kent, England |

| Age (2025) | 59 years |

| Nationality | British |

| Profession | English Actor, Writer, Entertainer |

| Height | 5 ft 10 in (1.78 m) |

| Education | Webber Douglas Academy of Dramatic Art |

| Known For | Role of Barry Evans in EastEnders |

| Spouse | Adele Williamson |

| Children | Sophie and Joseph Williamson |

| Residence | Isle of Sheppey, Kent, England |

Early Life and Education

Shaun Williamson was born and raised in Maidstone, Kent, where his down-to-earth upbringing shaped the strong, relatable personality that later won over millions of viewers. He attended Holy Family Roman Catholic Primary School and St. Simon Stock Catholic School before joining the Royal Navy at a young age. His time in the Navy taught him discipline and resilience—traits that would later serve him well in the competitive entertainment world.

After leaving the Navy, Shaun worked in several everyday jobs, including postman and holiday rep. However, his passion for performance never faded. Determined to chase his dream, he enrolled at the Webber Douglas Academy of Dramatic Art, one of London’s most prestigious drama schools. It was here that his natural charisma, comedic instinct, and emotional depth as an actor began to shine.

Start of Career and Rise to Fame

Shaun’s professional journey began with small television appearances in the early 1990s. His first role on EastEnders was brief, playing a paramedic. But fate had more in store for him. Just months later, he was offered a recurring part as Barry Evans, a lovable yet often unlucky character whose charm and vulnerability made him one of the most relatable figures in British soap history.

From 1994 to 2004, Shaun’s portrayal of Barry Evans turned him into a household name. Viewers laughed, cried, and connected deeply with his character’s emotional ups and downs. When Barry was written out of EastEnders in 2004, it marked both the end of an era and the beginning of a new chapter in Shaun’s professional life.

Career Beyond EastEnders

Shaun Williamson refused to be typecast. Instead, he embraced his past and turned it into comedy gold. His appearances in Ricky Gervais’s Extras and Life’s Too Short showcased his sharp self-awareness and willingness to parody his soap fame. These performances earned him respect as an actor with range, timing, and humility.

In addition to television, Shaun found tremendous success on stage. His theatre credits include Guys and Dolls, Saturday Night Fever, Oliver!, Porridge, and Chitty Chitty Bang Bang. Each role allowed him to show a different side of his acting craft—from musical comedy to heartfelt drama—proving that his talent extended far beyond television.

He also ventured into writing, penning the book A Matter of Facts in 2020. The book chronicles his journey into the world of competitive quizzing and provides a candid reflection on fame, reinvention, and lifelong learning. His BBC radio drama Eden’s End further demonstrated his creative versatility and storytelling depth.

Entertainment and Business Ventures

Shaun’s entrepreneurial spirit led him to create “Barrioke”, a live entertainment act blending music, comedy, and karaoke. The show, inspired by his “Barry from EastEnders” persona, became a massive success across UK festivals, pubs, and events. Barrioke perfectly captures Shaun’s ability to connect with audiences—mixing nostalgia with pure entertainment energy.

Beyond his stage and screen work, Shaun has become a popular figure in the British quiz scene. His intelligence and enthusiasm for general knowledge have earned him appearances on popular quiz programs such as Beat the Chasers and Celebrity Big Brother. These ventures showcase not just his acting skills but also his wit and authenticity as a public figure.

Personal Life

Shaun Williamson lives on the Isle of Sheppey in Kent with his wife Adele Williamson, whom he married in 2018. He has two children, Sophie and Joseph, from his previous marriage to Melanie Sacre. Despite the fame and challenges that come with show business, Shaun remains grounded, valuing family, friendship, and honesty above all.

He has openly shared stories about his early struggles and personal growth, earning admiration for his honesty. Shaun’s journey is not only about success but also about self-discovery, resilience, and embracing new beginnings at every stage of life.

Recent Work and Achievements

In recent years, Shaun has continued to entertain fans with Barrioke tours and television appearances. In 2025, he joined Channel 5’s Celebrity Puzzling, delighting audiences with his humor and intelligence. He remains an active figure in British entertainment—beloved for his warmth, relatability, and ability to adapt across genres and formats.

Shaun has also continued to perform in theatre productions, corporate events, and comedy festivals, proving his versatility and dedication to live performance. His energy on stage and natural charisma keep him in constant demand as a host and entertainer.

Legacy and Impact

Shaun Williamson’s legacy extends far beyond the screen. He represents the everyman who rose to fame, stumbled, and stood tall again through perseverance and self-belief. His portrayal of Barry Evans remains a staple of British television history, while his continued success in live entertainment showcases his timeless connection with audiences.

For many fans, Shaun embodies humor, humility, and heart—a combination that keeps him loved across generations. His journey from Kent’s working-class roots to national fame is not just inspiring; it is proof that talent, integrity, and reinvention can sustain a career even after the world stops watching your first act.

Conclusion

Shaun Williamson’s life and career highlight the power of authenticity and adaptability. From his early days in Maidstone to television stardom, from comedy roles to live music tours, he continues to reinvent himself while staying true to who he is. He stands as an example of how an English actor can evolve, survive, and thrive in an industry that often forgets its heroes.

Even after decades in entertainment, Shaun’s story is still unfolding—with laughter, music, and a legacy that refuses to fade.

FAQs

Q1: Who is Shaun Williamson?

Shaun Williamson is a British actor and entertainer best known for his role as Barry Evans in EastEnders and for his live show “Barrioke.”

Q2: Where was Shaun Williamson born?

He was born in Maidstone, Kent, England.

Q3: What is Shaun Williamson’s profession?

He is an English actor, stage performer, author, and live entertainer.

Q4: What is Shaun Williamson’s height?

He stands 5 feet 10 inches (1.78 meters) tall.

Q5: What is “Barrioke”?

“Barrioke” is Shaun Williamson’s popular live karaoke show, where he performs and interacts with audiences across the UK.

Q6: Is Shaun Williamson still acting?

Yes, Shaun remains active in television, theatre, and live entertainment, continuing to perform and host events across Britain.